Many hydroelectric plants are

evaluated according to the turbine’s performance, and many tenders are won (or

lost…) for a 0,1% of efficiency. But how important is the efficiency in a

hydroelectric power plant?

Talking about large size hydroelectric

plants, performance is a crucial aspect, or possibly the only one. An efficiency

increase of just 0,1% in a 100MW turbine causes an increase in the annual

production at about 500 MWh / year, with a revenue increase of approximately $

25,000 / year and $ 500,000 over 20 years of operation. For this reason, in

large-scale hydropower plants advanced design solutions of the turbine are

preferred, in order to achieve the maximum efficiency.

On the other side, for small hydropower

plants, the achievement of the maximum efficiency is no longer aimed, since an

efficiency increase does not always justify the increased costs of design and

production of the turbine. With an efficiency increase of 0.1% in a 100 kW

turbine, the power plant production increases at about 5000 kWh / year, with a

revenue increase of about $ 25 / year and $ 500 over 20 years of operation. It

is hence obvious that the economic sustainability of the most complex design

and construction solutions for turbines is not justified by the achieved

revenues.

Moreover, another extremely important

aspect must be taken into account. Even disregarding the economic aspect (which

is not at all negligible) and adopting advanced design and construction

solutions, efficiency values comparable with those of large-scale hydropower plants

cannot be achieved anyway. The reason is related to internal machine losses and

to the so-called “scaling factor". Without going into details about fluid

mechanics and turbo-machinery design, it is possible to explain this concept in

a simplified way.

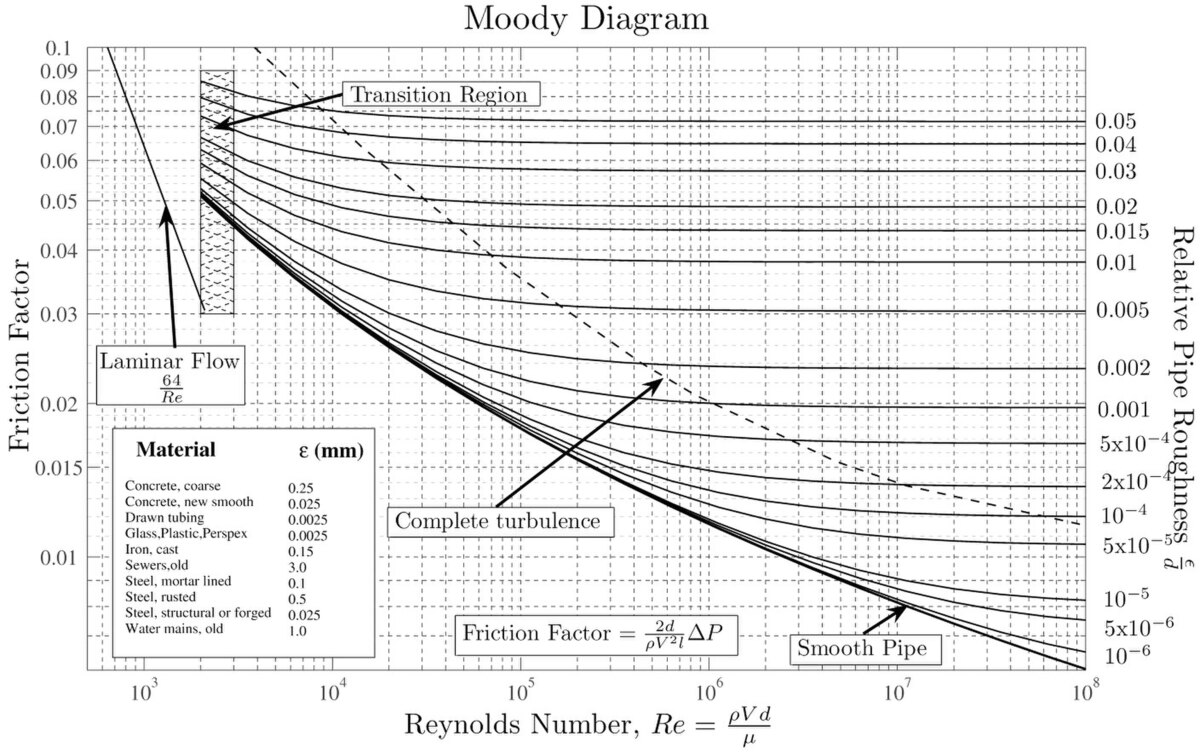

The hydraulic losses linked to the friction

strains between fluid and wet surfaces (impeller and volute), depend on the fluid

velocity and on the friction factor f (see the figure below - Moody diagram)

which in its turn depends on the characteristics of the flow field (laminar,

turbulent or fully developed turbulent expressed by the Reynolds number - Re in

the figure below), and on the relative roughness (ε / d in the figure below),

defined as the ratio between the absolute roughness of the wet surface ε and

the turbine diameter d. The roughness of the surface depends on the

manufacturing process, which does not significantly vary along with the machine

size. As a consequence, small machines are characterized by greater values of

the relative roughness ε / d and therefore by greater values of the friction factor

and of the linked hydraulic losses.

For this reason, in small size plants, advanced

design and construction solutions not only are unprofitable, but wouldn’t even allow

to achieve efficiency values comparable with those of large-scale plants. In literature some correlations have

been proposed for evaluating the variation in maximum achievable efficiency between

machines having different sizes, but these correlations should be applied with due

caution, taking into account the turbine geometry and expected characteristics

of the flow field inside the turbine.

HPP-Design considers all these aspects related to fluid mechanics and turbomachinery design. The obtained efficiency value can be used to calculate the plant production or to establish a baseline for the technical specifications of a tender, but does not replace the efficiency value provided and guaranteed by turbine manufacturers in the power plant construction phase. HPP-Design will give you a reasonable and accurate reference value to build your own project.

HPP-Design considers all these aspects related to fluid mechanics and turbomachinery design. The obtained efficiency value can be used to calculate the plant production or to establish a baseline for the technical specifications of a tender, but does not replace the efficiency value provided and guaranteed by turbine manufacturers in the power plant construction phase. HPP-Design will give you a reasonable and accurate reference value to build your own project.

For information, contact us or

send an email, you can also read our FAQ. HPP-Design develops day by day and

I advise you to register for our newsletter to be up to date on new releases.

Thanks to prof. Giovanna Cavazzini of

the University of Padua for her contribution.